>

Compact

linear Fresnel reflector (CLFR) power plant technology

1.

TECHNICAL AND COST FEATURES

CLFR

is a linear Fresnel reflector system with several or many linear

absorbers in the system, allowing the construction of plants in

the multi-megawatt range (Fig. 1). CLFR individual reflectors

can have the option of directing reflected solar radiation to

at least two absorbers in linear systems.

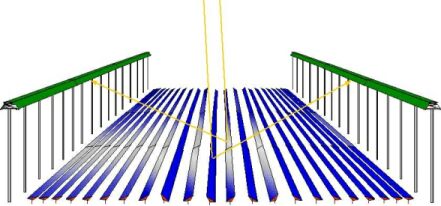

Fig.

1: Small segment of a large CLFR array showing segments of

two absorber lines. The tower height is about 15 m and typical

absorber lines will be 600 m long. (Raytrace by P. Le Lievre)

The classical linear Fresnel system has only one linear receiver,

and therefore there is no choice about the direction of orientation

of a given reflector. However, if one assumes that the size of

the field will be large, as it must be in technology supplying

electricity in the multi-megawatt class, it is reasonable to assume

that there will be many linear receivers in the system. If they

are close enough, then individual reflectors have the option of

directing reflected solar radiation to at least two receivers.

This additional variable in reflector orientation allows much

more densely packed arrays and lower absorber tower heights, because

patterns of alternating reflector orientation can be set up such

that closely packed reflectors can be positioned without mutual

blocking. The interleaving of mirrors between two linear receiving

towers is shown in Figure 2.

Fig.

2:

Schematic diagram showing interleaving of mirror rows to achieve

high site coverage without shading between adjacent mirrors.

The

avoidance of large reflector spacings and absorber tower heights

is an important issue in determining the cost of ground preparation,

array substructure and absorber tower structure costs, steam line

thermal losses and steam line cost. The more flexible CLFR still

delivers the traditional benefits of a Fresnel reflector system,

namely small reflector size, low structural cost, fixed receiver

position without moving joints, and the ability to use non-cylindrical

receiver geometry. But further, our CLFR power plant concept is

a serious attempt to reduce all major cost in a solar thermal

electrical system, and includes the following additional features

which enhance the system cost/performance ratio:

- The array

uses flat or elastically curved reflectors instead of costly

sagged glass reflectors. The reflectors are mounted close to

the ground, minimising structural requirements. The heat transfer

loop is separated from the reflector field and is fixed in space

thus avoiding the high cost of flexible high pressure lines

or high pressure rotating joints as required in the trough and

dish concepts.

- The heat

transfer fluid is water, and passive direct boiling heat transfer

can be used to avoid parasitic pumping losses and the use of

expensive flow controllers.

- An inverted

cavity receiver has been designed using steel boiling tubes

which can be directly linked with an existing fossil fuel plant

steam system. This is much cheaper than evacuated tubes used

in trough plants. Direct steam generation is much easier with

this absorber than with tubular absorbers in trough collectors.

- Maintenance

will be low because of ease of reflector access for cleaning,

and because the single ended evacuated tubes can be removed

without breaking the heat transfer fluid circuit.

Basic CLFR

arrangements include analogues of the east-west axis parabolic

trough, the north-south axis parabolic trough, and the polar axis

parabolic trough. Large arrays are horizontal and NS axis arrays

collect slightly more energy than EW arrays.

2. APPLICATIONS

Basic CLFR

arrangements include analogues of the east-west axis parabolic

trough, the north-south axis parabolic trough, and the polar axis

parabolic trough. Large arrays are horizontal and NS axis arrays

collect slightly more energy than EW arrays.

Retrofit

Supply of Heat to Fossil Plant

The technology

was designed for saturated steam boiling and is suitable for this

purpose up to about 365°C. An ideal market is provision of thermal

energy between 300°C and 365°C to large coal and oil fired Rankine

cycle generating plant. Approximately 100 MW(e) peak equivalent

of solar energy can be supplied to such plants for reheat alone

at 300°C, and the latter can be retrofitted to existing plant.

The CLFR

powerplant design was a winner of a A$2 million Australian Greenhouse

Office Showcase commercialisation grant and was intended be built

near Rockhampton by AUSTA Energy and Stanwell Corporation, but

this project fell into difficulty after the original project manager

AUSTA was abolished by the Queensland Government. However, due

to new legislative incentives in NSW, the project activity has

now shifted to the Hunter Valley there where a 25 MW(e) project

is planned for 2003/4 next to Liddell power station. Two other

similar sized sites have been located for future projects nearby.

The solar

array will be a direct steam generation system and will feed steam

or hot water directly into the power station steam cycle. The

first CLFR plant will be used for preheating feed water going

into the reheating circuit, although subsequent plant will be

able to be used for main boiler steam injection in to the cold

reheat line. The design steam delivery conditions for the Liddell

project are 265°C and 5 MPa wet steam.

The technology

can, in principle, allow a higher peak output per km2 of ground

area, but the current cost optimum is to be pegged at about 125

MW(e) per km2. As a comparison, an 80 MW(e) LS3 plant in California

occupies about 1.35 km2, about 60 MW(e) per km2.

The design

approach is to minimise costs by using existing power block equipment

and to maximise greenhouse gas savings by directly offsetting

coal usage. This project is particularly attractive because it

offers a low risk, low cost transitional path for commercialising

solar thermal energy. The cost of electricity is estimated to

be about $A 0.07 per kWh, close to the price of wind generation.

These costs are well below those of competing technology, and

occur for a variety of reasons.

Technology

The CLFR

will use an inverted cavity receiver containing a water/steam

mixture which becomes drier as the mixture is pumped through the

array. The steam is separated and flows through a heat exchanger

where the thermal energy passes to the powerplant system. In the

initial plant, the reheat cycle only requires steam at 265°C.

Initially

a Chrome Black selective coating will be used but a new air stable

selective coating is being developed for higher temperature operation

required by stand alone plants (320-360°C). The optical efficiency

of the receiver is very high and uses no auxiliary reflectors.

The design is in confidence.

The reflectors

are of glass slightly curved and laminated with a composite/metal

backing. Each reflector row is 600 metres long, and contains three

segments of 200 metres each of which are tracked by one motor/gearbox.

The structure is below is lightweight coated steel. Headers are

minimised, with steam down and up each receiver row. The entire

system is extremely simple and requires one laptop computer for

operation.

Costs are

kept low by using water as a heat transfer fluid, a low cost structure

with reflectors close to the ground, a low cost receiver which

is composed of mild steel pipe, and exceptionally low reflector

costs due to advanced laminated construction. The installed array

and heat exchanger cost is about $A900 peak electrical kilowatt,

about $US500. O&M is low because cleaning can be done manually

at ground level. This is less costly than an automatic cleaning

system.

3.

STAND ALONE POWER GENERATION

In NSW there

exist two regions which, although relatively small compared to

the area of NSW, make up about 100,000 km2 of relatively flat

country. In these regions, the sunlight hours are in excess of

9 hours a day on an annual basis, substantially higher than in

coastal NSW and far higher than in Europe. Currently, it is thought

that about 300 MW(e) of solar generation can be utilised from

these sites without grid extension, but the resource is potentially

enormous with grid extension. To give a sense to proportion, the

CLFR technology, working with standard steam turbine and generator

sets, could satisfy the entire electrical usage of Australia with

only 1000 km2 of such land. There exist many such suitable sites

around the world.

The CLFR can

be used with solar/gar co-firing in the initial stages to allow

lower cost. This is necessary because the power block is now about

twice as expensive as the collector field, and the power block

must be run a longer time to amortise costs. It is hoped the first

solar/gas plant can begin construction in NSW at the 100 MW level

by 2005. The unsubsidised cost is estimated at $A0.07 per kWh

initially for combined gas and solar output. Reducing the gas

fraction will raise the price.

A longer

term solution to this problem is to provide thermal storage for

the solar energy collected. This would allow the power block to

be operated on a round the clock basis, although it is likely

that a 12 hour operational period would be expected initially

because of the pool pricing of electricity. Sensible heat storage

in oil and molten salt are being considered for this line of development.

It is hoped a storage plant can be installed in NSW in about 2007.

The cost of a plant with 50% capacity factor and 80% solar fraction

(20% gas) would be close to that of the solar/gas plant above.

Eliminating the gas component would raise the cost to around 8

Australian cents per kWh. However, the extent of collector cost

reduction is not clear, and large production quantities could

lead to lower costs.

Such CLFR

technology can be installed in Europe, China, North Africa, the

United States, and in many other regions.

4.

END USE THERMAL ENERGY SUPPLY

The technology

can supply process steam up to 365°C instead of electricity. It

is suitable, with towers and receivers in scaled down form, to

provide low cost solar steam for large absorption chillers allowing

double and triple effect chillers to operate and higher temperature

ORC engines.

In this type

of application it would be similar in output to evacuated tube

systems, but may be less expensive in capital cost. It could help

run a pressurised water storage system in combination with adjacent

evacuated tube arrays. It would also be able to run more efficient

ORC turbines at higher temperatures than evacuated tube systems,

so that electricity generation would be cheaper. It also has daylighting

attributes when mounted over large spaces which evacuated tube

systems do not. But it is more complicated than evacuated tube

systems because of tracking requirements.

The system

would have a spectacular look from above, and an attractive appearance

from below as an effective daylighting device. On cloudy days

the array 'slats' could be opened up to allow more light in because

no useful power can be obtained without solar beam.

5.

UNIVERSITY WORK

The CLFR

concept was first developed in the Solar Energy Group in the early

1990's. The primary IP is now held by Solsearch Pty. Ltd. The

University is contributing optical modelling and absorber design

experience to the project, in an ongoing cooperation with the

project management company Solar Heat and Power (SHP). High temperature

selective coatings are being developed for the technology by the

University for later stand alone plants.